THE

NETWORK

THE STRENGTH OF OUR NETWORK: SERVICE AND EXPERTISE

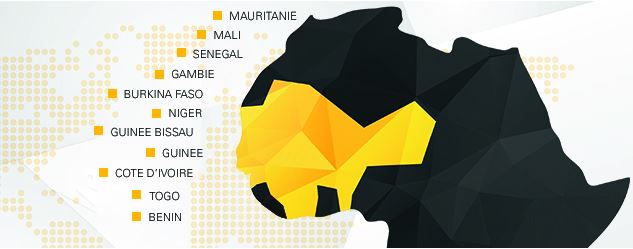

Present in the African market for 160 years and a CAT dealer since 1932, JA Delmas and its network has over 2000 collaborators spread over 11 West African countries and 11 agencies.

Bénin Equipements, Burkina Equipements, Manutention Africaine Côte d'Ivoire, Bissau Euipamentos, Gambie JAD, Atiko Guinea, Manutention Africaine Mali, Mauritrac, Manutention Africaine Niger, Saudequip, and Togo Equipements.

Our areas of activity are centered on the Mining, Construction & Forestry, Energy & Transportation, and Industrial Equipment fields.

To reinforce our international presence in these fields, we locally offer in West Africa a complete package of services for our clients. We provide a large range of new, used, rental material, and stock original spare parts.

Our spirit of service, our foothold and the power of our network, make the JA Delmas network the go-to partner to support you in your projects across West Africa.

Today we are hiring

Experienced Maintenance Technician - PSC Mines M/F

Site Minier - Contract Permanent contract

Description du Poste

With an increase in the number and complexity of our mining projects, we are looking for talented Maintenance Technicians/Product Support Coordinators (PSCs) driven by high-level technical expertise but also by the concern for customer satisfaction (service orientation, availability, knowledge transfer)!

The Senior Maintenance Technician/PSC is the dealer representative on the customer's site

Based on a mining site, he is responsible for the after-sales service of new machines sold by JA Delmas

His role is to provide the customer with the best service for fleets he is responsible for, in terms of availability and maintenance costs

Being the dealer's representative, the PSC must always work in compliance with the manufacturer's technical rules. He must in particular ensure that the site's safety instructions are respected and enforced

To succeed he must establish a smooth relationship with the client

He will try to be as available as possible and shall if necessary intervene outside normal working hours and in particular at night, within the limits of working regulations.

He will guarantee

- the monitoring of the machines under warranty and under his responsibility

- availability of machines under contract and under his responsibility

- assistance with services on machines under warranty, reports, SIMS tickets

- assistance with dealing with repairs and maintenance work

- technical reports, expert feedback

He will report regularly to his management

He will also be responsible for the continuous coaching and tutoring of his collaborators. Thus he will guarantee their rise in technical and organisational skills

Profil Recherché

Solid academic background in Technical Maintenance

- At least 5 years' experience as a Maintenace Technician or in a Heavy Equipment Workshop

- Excellent skills in Hydraulics, Electricity, Motor, Transmission, but also Industrial Maintenance (an advantage especially on our electrical equipment like Cable Shovels, Electric Drills, etc.)

- Knowledge of the Mining environment is a definite advantage

- Knowledge and experience of CAT equipment and in particular Mining Equipment:

Trucks 777 to 793

Dozers D8 to D11

Shovels 6030 to 6060 (ex Bucyrus RH series)

Graders 14 to 24

Loaders 966 to 994

...

- Very good command of SIS and ET

- Knowledge of VIMS is appreciated

- Driving license and CACES mandatory

Fluent English and French

African languages are welcome

This position requires a high degree of autonomy while facilitating teamwork and in particular supporting less experienced colleagues

Must be at ease in a multicultural environment

This type of position is most commonly based on a FIFO rotation system